Introduction of Vitrified Bond Grinding Wheel (Diamond & CBN) 2019

1.Introduction of vitrified bond grinding wheel

2.Introduction of vitrified bond

3 Introduction of vitrified bond diamond grinding wheel

4 Introduction of vitrified bond CBN grinding wheel

1. Introduction:

Vitrified bond grinding wheels are mainly made of abrasives(conventional, CBN, diamond abrasives) and vitrified (ceramic) bond sintered in a certain proportion. The applications include rough grinding, semi-finish grinding, finish grinding and polishing for the surface of some products, molding grinding for the products with a large area, and grinding of superhard abrasive sintered bodies, etc.

2.Summary of vitrified bond:

Vitrified bond has good thermal stability, good brittleness, good rigidity, and controllable porosity. The vitrified bond super abrasives grinding wheel features high strength, self-sharpening and easy dressing. The bonding strength is better than that of resin bond diamond/ CBN grinding wheel. The chip capacity of the working surface is better than that of metal bond diamond/ CBN grinding wheel. It does not block easily, sharp cutting, high grinding efficiency, small thermal expansion, easy to control the accuracy, and stable grinding.

2.1 Performance of vitrified bond

The bond performance determines the quality of the grinding wheel, so the following performance of the vitrified bond should be: strength, hardness, grain size, fire resistance, wettability, thermal expansion and etc.

Bond strength:

When the external force acts, the grinding wheel has the ability to resist the external force without being destroyed. This is the mechanical bond strength(ie. bond strength). Mechanical strength mainly includes 4 kinds: tensile strength, rupture strength, impact strength, and compressive strength.

Refractoriness:

The firing temperature of the grinding wheel is determined by the bond refractoriness.

When the firing temperature is constant, if the refractoriness is high, the liquid content in the bond will be less, which will cause the abrasive grain falling off. The reason is that the bonding between the bond and the abrasive grain is not strong, and the strength and hardness of the grinding wheel is very low. Therefore, the grinding wheel should be fired at a lower temperature.

The main reasons affecting the refractoriness are chemical composition of the bond, the dispersion of raw materials and additives of the bond, grain size, and temperature rise rate.

Wettability:

The wetting angle( expressed by θ ) refers to the wettability of the bond to the abrasive grain surface.

The smaller the wetting angle is, the better the wetting performance is. For the same kind of the bond, the wetting angle is proportional to the temperature, and the wettability is enhanced when the temperature is high.

Thermal expansion

Thermal expansion is mainly measured by the thermal expansion coefficient. The matching of expansion coefficient between the bond and the abrasive directly affects the strength, manufacturing technology and performance of the grinding wheels.

The main factors affecting the thermal expansion coefficient of the bond: crystal structure and

The bonding strength of raw materials, chemical composition of the bond and the types of additives, this is because there is the difference between the expansion coefficient of each oxide, finally, the expansion coefficient of the bond is different. The phase composition of the bond after firing, homogeneous polycrystalline transformation.

Effect of different oxides on thermal expansion performance of vitrified bond

2.2 Types of vitrified bond

There are many classification principles for the vitrified bond, mainly introducing the following:

2.2.1 There are fused bond, sintered bond, semi-fused (semi-sintered)bond according to the relationship between the firing temperature of the grinding wheel and the refractoriness of the bond.

Sintered bond:

The refractoriness is higher than the firing temperature of the grinding wheel. When the temperature reaches the firing temperature, only a few bond melt and forms the liquid phase. Observe the microstructure after firing, in addition to the glass phase, there are many crystals. Similar to the microstructure of ceramics, it is a multiphase system. Usually, the raw materials of the sintered bond are clay, feldspar, quartz and etc. In some cases, add a small amount of talc. The percent of chemical composition is as follows:

SiO2:55%-71%

Al2O3:17%-22%

Fe2O3 :1.5%

MgO: 0.5%-2.5%

K2O+Na2O:4%-13%

Fused bond

The firing temperature of the fused bond is higher than its refractoriness. At firing temperature, almost all the bond melt into a liquid phase and evenly coat around the abrasive grains. After cooling, form glassy microstructure. Although most of them are glass phase, it is impossible for a little crystalline phase to exist in the microstructure of the fused bond. Of course, we do not hope there is crystalline phase, because crystalline phase exists in the bond, especially when there are coarse and uneven grains, the homogeneity of the glass phase structure will be destroyed, and then it is easy to produce the structural defects such as micro-cracks, which greatly reduces the strength of grinding wheel.

Using the special formula and correct technology can promote the formation of glass-ceramics structure, which greatly improves the strength of the grinding wheel. However, manufacturing technology is not easy to control, and technology is difficult. In the production of abrasives, the fused bond is often used. Because more flux materials exist in the fused bond, which makes the refractoriness of the bond decrease. Traditionally, flux materials include feldspar, talc, borax glass, fluorite, spodumene, and etc. In recent year, various pre-fused glass materials have been used, such as borosilicate glass, lead-borate glass, and some chemical raw materials. The percent of the chemical composition of the fused bond is as follows:

SiO2:55%-71%

Al2O3:17%-22%

Fe2O3:1.5%

CaO – 4.5%

MgO: 0.5%-2.5%

K2O+Na2O: 4%-13%

B2O3: 5%-15%

Fused bond is often used infused alumina abrasives, and some SiC grinding wheels have tried to use a fused bond.

Compared with the sintered bond, the fused bond has the following features:

- The fused bond features low refractoriness. The bond almost melts into the liquid phase at the firing temperature. Therefore, the fluctuation of firing temperature has little effect on its performance, and the quality of abrasives is relatively stable.

- The fused bond has better reaction ability and high-temperature wettability. The reaction ability ranges from 8% to 25%, which is good for improving the bonding condition between the bond and abrasive grains. Usually, the strength of the fused bond grinding wheel is higher than that of sintered bond ones.

- On the same condition of the hardness of grinding wheel, the amount of fused bond is less than that of a sintered bond. So, there are more pore and looser abrasive structure on the surface of the abrasives, which can improve the grinding efficiency, and reduce the burn to the workpiece.

- Fused bond contains higher alkaline oxide, which can promote the SiC abrasive be decomposed at high temperature, and finally, defect products will be obtained. Therefore, should consider the bond for manufacturing SiC grinding wheels.

Semi-fused(semi-sintered) bond

Its refractoriness is similar to firing temperature, sometimes is the same as firing temperature. Its performance is between the sintered bond and fused bond. This kind bond can improve the fluidity, reaction ability and high-temperature wettability of grinding wheel raw materials. But it also reduces the strength of abrasives. For SiC grinding wheel, it can avoid the defect products caused by the decomposition of SiC when using this kind of the bond, and also effectively avoid the deformation and foaming. This kind of bond is used in the manufacture of low concentration SiC grinding wheel and fine-grain and high hardness fused alumina grinding wheel.

High-temperature bond and low-temperature bond in term of firing temperature

1000℃is the boundary between 2 types of bond. The bond of firing temperature higher than 1000℃is called the high-temperature bond, and that of lower than 1000℃is called the low-temperature bond. There is no absolute concept for high and low temperature in practical operation. This limit is not so strict. Low-temperature bond is mainly used in the manufacture of special abrasives, such as superhard (diamond & CBN) grinding wheel, honing stones, super honing stones, and etc. High-temperature bond is usually used in vitrified bond abrasives.

2.2.3

There are 2 kinds of vitrified bond, general purpose bond and professional bond in term of the application. General purpose bond has fused alumina grinding wheel bond, SiC grinding wheel bond, and fused alumina and SiC grinding wheel bond. Professional bond has high speed grinding bond and the bond of grinding wheel for steel ball.

2.3 Disadvantage of vitrified bond

1) Vitrified bond features larger brittleness, poor fatigue resistance, and poor impact resistance.

2) The manufacturing technology of low temperature firing vitrified bond for diamond & CBN is much more complicated than that of traditional resin and metal bond.

3)The grinding performance of the vitrified bond grinding wheel is between that of resin and metal bond.

3.Brief introduction of diamond vitrified bond grinding wheel

Vitrified bond diamond grinding wheel is applied to synthetic diamond. Diamond is the mineral composed of carbon element and it is the allotrope of carbon element. It has 2 different crystal structures: a cubic diamond structure and a hexagonal diamond structure. The most common structure is a cubic diamond structure.

Diamond Crystal Structure

Diamond is equivalent to the hardness of other minerals

Applications of vitrified bond diamond grinding wheel:

It is used for rough and finishes grinding PCD, PCBN tools to replace resin bond diamond grinding. In ultra-precision grinding of a silicon wafer, vitrified bond diamond grinding wheel is used for rough grinding, and then finish grinding by resin bond diamond grinding wheel. It can be used for precision grinding of PDC related products, also for high-speed grinding of teletron, magnetic materials, and ceramic products.

Vitrified bond preparation process:

This figure is a general purpose example, and different applications of the vitrified bond, there is different for raw material mixture ratio and manufacturing technology.

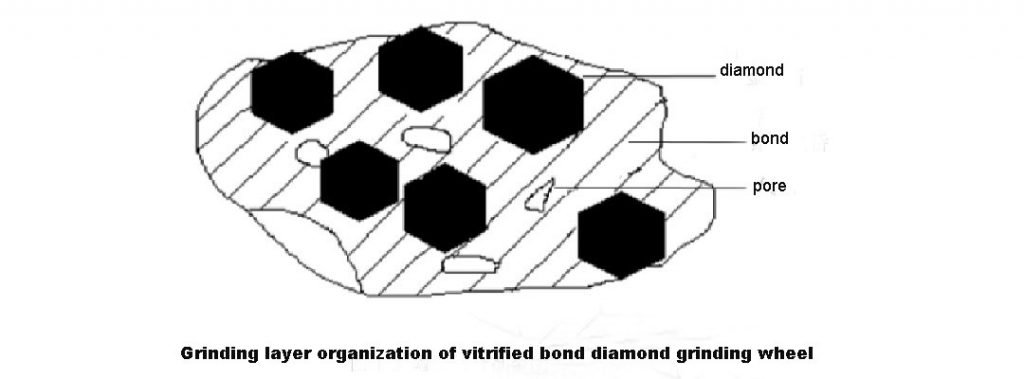

Organization Structure of Vitrified Bond Diamond Grinding Wheel

Vitrified bond diamond grinding wheel preparation process

The main study focus on the diamond vitrified bond grinding wheel

- Development of vitrified bond with low temperature sintered, high strength and low expansion coefficient

- Study on the improvement of toughness and reinforcement of vitrified bond

- Study on the surface modification of diamond abrasive

- Study on the mutual affinity and invasiveness between vitrified bond and diamond abrasive

- Study on the preparation process parameters of vitrified bond diamond wheel

- Study on the structural improvement of vitrified bond diamond wheel

- Study on the optimum grinding parameters and grinding methods of vitrified diamond grinding wheel

4.Introduction of CBN vitrified bondgrinding wheel

Introduction of CBN abrasives:

Cubic boron nitride(CBN) is synthesized from hexagonal boron nitride(HBN), using alkali metals, alkali earth metals or their nitrides are used as catalysts to transform into diamond-like crystal structure under high pressure and high temperature. The whole process is similar to that of graphite synthesizing diamond. CBN is a diamond-like crystal structure.

Schematic diagram of CBN crystal structure (a) and crystallographic cell (b)

The hardness and thermal conductivity of CBN are only lower than that of a diamond. Compared with diamond, CBN has 2 main advantages: one is that CBN has good thermal stability, the other is that CBN has chemical inertia for iron group element compared with diamond.

Table1-1 Nature Contrast of CBN and Nature Diamond

Applications of vitrified bond CBN grinding wheel:

Vitrified bond CBN grinding wheel features high efficiency, and longer service life in the process of machining, sharpen cutting, and small grinding force. It can easily shape and dress with high grinding precision and less grinding heat.

It is widely used in the key parts of the automatic engine such as camshaft, crankshaft, the piston of air conditioning refrigeration compressor, cylinder, upper cover, lower cover, precision machinery( machine tool guideway, screw, etc.), bearing, metal processing abrasives, and other industrial fields. The material of the workpiece is various kinds of brittle hard alloy steel, stainless steel, high-speed steel, high-temperature alloy, and titanium alloy.

Traditional vitrified bond is mixed by clay, borax glass, zirconia, and other raw materials evenly according to the proportion, as shown below figure.

The flow chart for preparation of traditional vitrified bond

Glass bond and glass-ceramic bond

Glass bond and glass-ceramic bond must be mixed with raw materials and melted at high temperature to form homogeneous glass phase, and then water quenching and ball milling to obtain a finer grained bond.

Glass binder and glass-ceramics binder must be mixed with raw materials and melted at high temperature to form homogeneous glass phase, then water quenching and ball milling to obtain finer-grained binder. The flow chart is as follows.

The preparation of glass bond and glass-ceramic bond

Distribution condition of the bond in CBN abrasives

The preparation process of CBN vitrified bond grinding wheel:

- Ingredients: calculate all kinds of raw materials(CBN, ceramic bond, agglomerant, fused alumina, and other accessories), weigh them accurately, and the weighing accuracy is 0.001g).

- Mixing: First put CBN abrasive into stainless steel basin, and add appropriate dextrin solution to mix, and grind the material evenly with spoon, make the surface of CBN abrasive uniformly coated with a layer of dextrin solution, and then add vitrified bond through sifting, making the bond evenly wrap and adhere to the surface of CBN abrasive, finally add other molding additives and mix evenly.

- Forming: Put the forming materials into the mold and press into the grinding wheel of the corresponding size on the press.

- Drying: In order to make the green body of grinding wheel have certain consolidation strength, and add temporary consolidation wetting agent or bond with water when mixing materials. So the green body of a formed grinding wheel contains 5-15% water. In order to prevent water from becoming vapor expanding during the subsequent sintering process, and to improve the strength of the green body, it needs to dry for 24 hours at room temperature and then dry for 10 hours at 50℃ or 80℃.

- Sintering: The bond in the dried green body of grinding wheel is mainly bonded with CBN abrasive by temporary bond, so the strength of the green body is low. It should make the bond in the green body vitrify, and have a certain physical and chemical reaction with the abrasive in order to make the products have the corresponding mechanical strength. There are 3 stages: heating, heat preservation and natural cooling in the whole firing process.

The study focus of vitrified bond of CBN grinding wheel:

- The preparation process of the bond has an obvious effect on the refractoriness of the bond. It can reduce the refractoriness and homogenization of bond by pre-melting and vitrification treatment, and improve the performance of the grinding wheel to a certain extent.

- The composition of the vitrified bond is one of the key factors affecting the CBN wheel. Glass-ceramic bond has excellent mechanical performance and is suitable for the preparation of high strength vitrified CBN grinding wheel. It is the main development direction of the vitrified bond.

- High-temperature wettability of CBN abrasive for vitrified bond affects the state of the bond between abrasive grains. Good wettability between the bond and abrasive is good for the development of bridging phase of the bond. Not good wettability causes bond aggregation.

Conclusions:

With the development of vitrified bond, the manufacturing technology of superhard vitrified bond grinding wheel is becoming more and more mature. Choose suitable superhard grinding wheel, make grinding efficiency higher, grinding quality more perfect, and grinding cost lower.

.webp)